Heat

Description

Basic Info.

| Model NO. | ONL-XB700 |

| Speed | High |

| Sealing & Cutting | Heat-Sealing Cold-Cutting |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Yes |

| Type | Non-Woven Bag Making Machine |

| Certification | CE |

| Export Markets | Global |

| Dimension(L*W*H) | 10000X2700X2000mm |

| Bag Width | 200-580mm |

| Bags Type | Kind of Bags |

| Bag Making Thickness | 35-100g.S.M |

| Loop Handle Thickness | 60-120g.S.M |

| Key Selling Points | Multifunctional |

| Loop Handle Length | 370-600mm |

| Weight | 3600kg |

| Production Speed | 40-100psc/Min |

| Bag Length | 100-800mm |

| Material | Non Woven Bag |

| Condition | New |

| Transport Package | Plastic Film with Pearl Cotton |

| Trademark | ALLWELL |

| Origin | Zhejiang, China |

| Production Capacity | 30 Set/Sets Per Month |

Product Description

Product Description

ONL-XB700 Non-Woven 5 in 1 Bag Making Machine With Handle Online

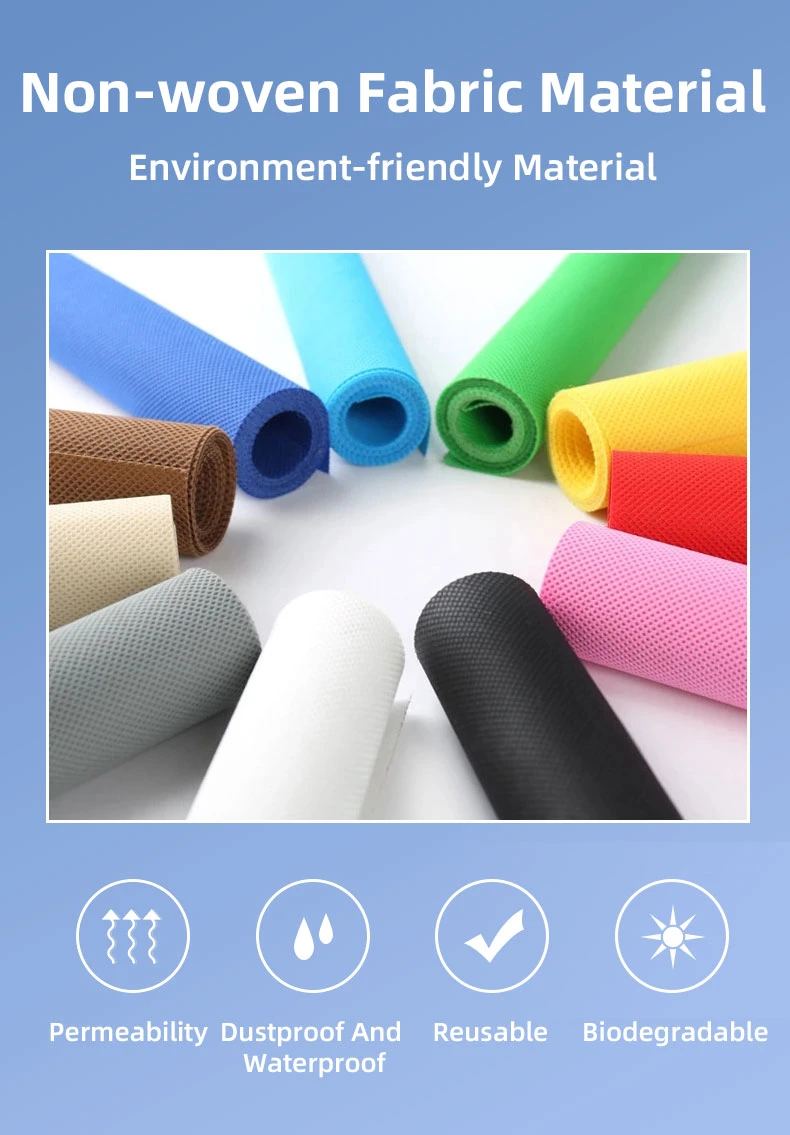

ONL-XB700 Bag Making Machine can produce 5 types bag: Box Bag / Handle Bag / T-shirt Bag / D cut Bag / Zipper Bag. Non-woven bag compare with plastic bag and paper bag, it is more eco-friendly and durable, more and more company start to use non-woven bag for packing. And we also can according to customer`s requirement, add some function or doing special size to the machine, customize machine for each customer.

Product Parameters

| Machine Model | ONL-XB-700 | ONL-XB-800 | ONL-XC-700 | ONL-B700 |

| Production Speed | 40-120 pcs/min | 40-120 pcs/min | 40-120 pcs/min | 40-120 pcs/min |

| Feeding Roll Width | 1.25m | 1.45m | 1.25m | 1.25m |

| Bag Gusset Range | 0-18cm | 0-18cm | can not do box bag | 0-18cm |

| Bag Width Range | 10-80cm | 10-80cm | 10-80cm | 10-80cm |

| Bag Height Range | 20-58cm | 20-68cm | 20-58cm | 20-58cm |

| Handle Length Range | 37-60cm | 37-60cm | 37-60cm | can not make handle |

| Handle Gram Weight | 60-120 G.S.M | 60-120 G.S.M | 60-120 G.S.M | can not make handle |

| Bag Gram Weight | 35-100 G.S.M | 35-100 G.S.M | 35-100 G.S.M | 30-100 G.S.M |

| Power | 22KW | 23KW | 20KW | 15KW |

Application

About Us

Company Profile

FAQ

Q1. How long will your engineer reach our factory?

Our After-sales Specialist would contact with you, confirm the final scheduling according to your reasonable request.

Q2. How many days will you finish installing?

We will finish installation and training within 7-10 days.

Q3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 80USD one day per person.

Q4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

Q5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

Q6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

Q7. Does your engineer understand English?

Our engineers understand a little English. All of our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

Q8. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.weour after-sales department with 30 engineers.Our engineers will take a solution video according your description.

Q9. How many workers do we need running those machines?

Except two for bag making machine, flexo printing machine, slitting machine, ultrasonic sewing machine, hydraulic punching machine only need one person for each.

Prev: Customized Cutting Stripping Crimping Soldering Tinning Machine for Wire Cable Guangdongzhengjia

Next: Fast Speed Customized CNC Plate/Sheet Fiber Laser Cutter/Cutting Machine

Our Contact